Technical Data

The COMPACT 5 - integrating Tuck - in and Hot-Melt closing in one machine - our latest innovation,

offering extraordinary flexibility and is therefore particularly suitable for industries like contract packing, pharmaceuticals, cosmetics and food.

With 10 stations the COMPACT 5 provides enough space for different types of controls (e.g. print check, pharma code check, product presence check, etc.) making it a perfect solution finished to pharmaceutical standards. Our patented, fully adjustable size star STELLA 68 especially designed for the

COMPACT 5 with 10 stations, allows an easy and quick change over between carton formats in 15 minutes without any replacement size parts on

the size star. UNIQUE TO UET! The COMPACT 5 is driven mechanically. The function control is handled by a PLC. With its special developed and patented size Star "STELLA 10" the COMPACT 5 is the most flexible Compact Cartoning Machine worldwide. It can be configured with up to 5 flexible filling stations and, due to its enormous size range the COMPACT 5 offers the appropriate and ideal solution for contract packers. The COMPACT 5 can be configured to handle various closing systems - tuck-in, hot-glue or a combination of both. Each COMPACT 5 is tailor made. It can be equipped with many industry specific options. Especially for the pharmaceutical industry you can opt e.g. for a stainless steel machine plate, for pharma-code or track-and -trace systems, for the most different coding systems on the market or you can group the complete packed products for further processing.

Always considering our customer's requirements!

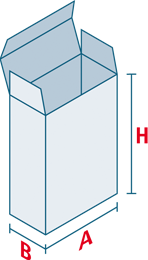

SIZE RANGE COMPACT 5

| Compact 5 | |

|---|---|

| A | 25-120 |

| B | 18-90 |

| C | 60-180 |

(A/2+B)≤140 mm All mentioned dimensions in mm - Special sizes on request.

Space requirements: approx. 2,5 m²

Output: up to 50 boxes/minute according to product load cycle of the operator and/or the feeding system.